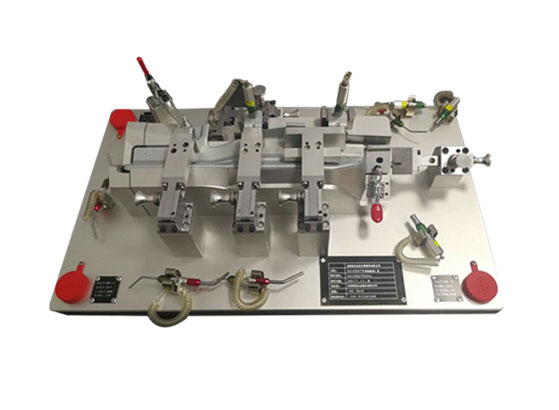

Product quality inspection jigs

What is the test jigs?

Checking jig is a jig used to evaluate the accuracy of the finished product in the process of processing and assembling.

Đơn vị thiết kế, gia công đồ gá

The company designing and processing the jigs

Anttek Vietnam Equipment JSC is specialized in designing and manufacturing test jigs according to customers 'requirements, understanding customers' ideas and making suitable jigs.

Contact for free consultation and the best quote

Hotline: 0988 688 336

Factors affecting test tolerance.

When making a test fixture, we should pay attention to all causes of the tolerance:

2. Tolerance to adjust the jigs

3. Tolerance due to worn fixtures

4. Tolerance due to the temperature change while testing.

Checking helps minimize or eliminate the causes of that influence

The structure of the test jigs

There are many test jigs depending on the purpose of use such as: dimension check jigs, profile test jigs, surface quality test jigs, defect check jig of internal part assembly process, ... but all types of test jigs have the following basic structures:

2. Positioning structure

3. Clamping mechanism

4. Measuring and checking structure

5. Other auxiliary structures

The function of the test jigs:

Assembly jigs make it easy and speed up the inspection process, to avoid product failures before moving on to the next operation or factory.It also helps to automate the inspection process, save time.

Principle of operation

The test jigs often have the following general principles of operation:

2. Assign the part to the positioning parts of the jig (in accordance with the working position of the part, part assembly or machine)

3. Clamp the part firmly with the clamping mechanism of the jig

4. Measure, check by measuring, checking device